When it comes to designing structures, the foundation is a critical component that contributes to the stability and longevity of the structure. While concrete foundations have been the conventional choice, caissons can be a better alternative depending on soil conditions. With their quicker, more cost-friendly installation, caissons may be the better choice for your next project.

Vibratory Caissons

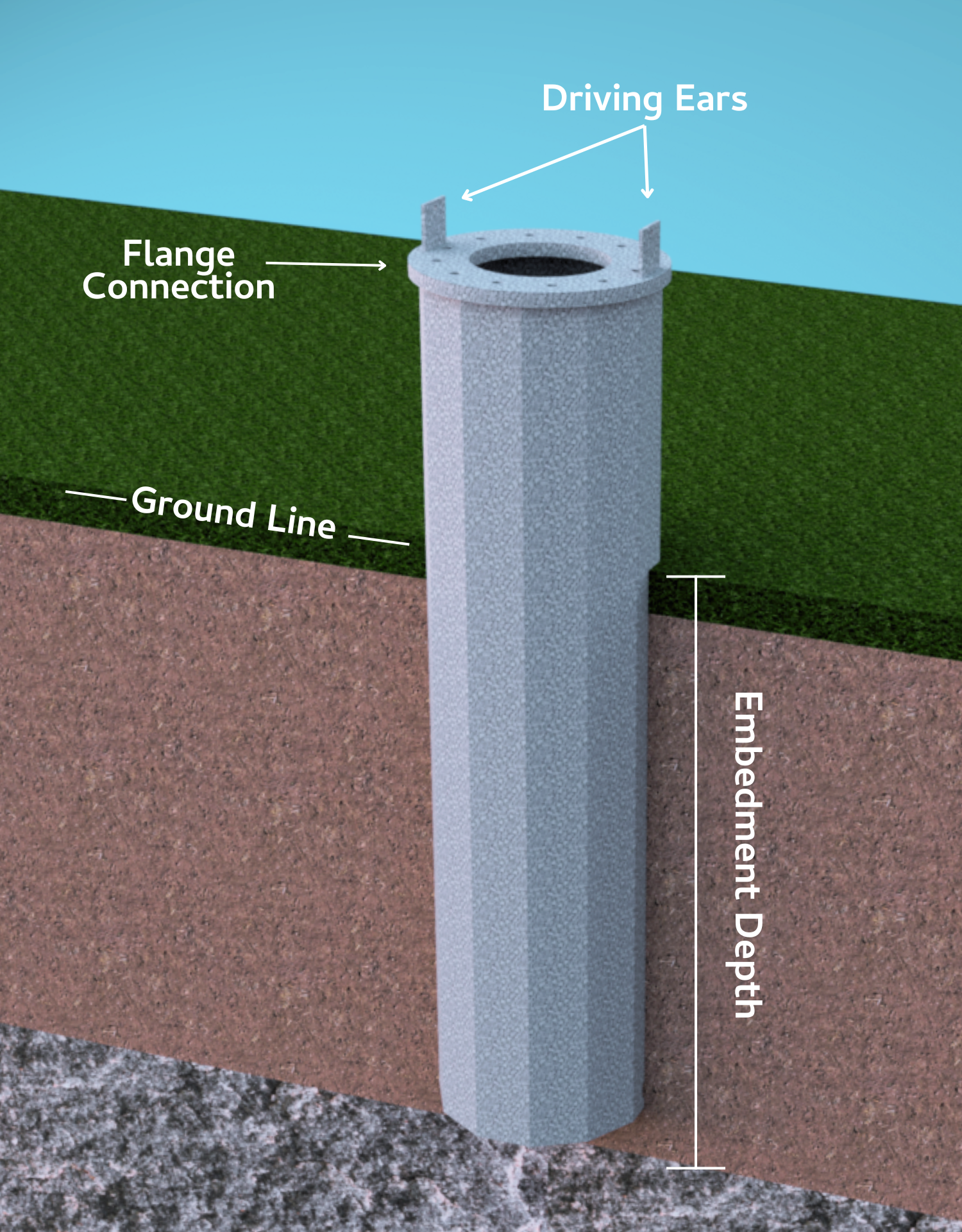

The most common choice of caisson for steel structures are vibratory caissons. These are an ideal option for those looking for faster installation and cost-effectiveness. Vibratory caissons are pipes or bent plate tubes that are vibrated into the ground using driving ears, providing easy installation. They are connected to the structure with a base plate connection. This is achieved by bolting the flange of the structure to the inside or outside of the caisson.

Vibratory caissons have been successfully used, however, they must be installed in suitable soil. Vibratory caissons can be used in a variety of different soil types but are most often used in soils with poor cohesion. These types of soils cause trouble in the wall stability drilled shaft making it hard to pour concrete into. Rocky soil conditions can cause the caisson to hit refusal, preventing it from going down any further into the ground. A thorough assessment of soil conditions is crucial when considering this method.

Considerations for Vibratory Caissons

There are a few key components when using caissons for foundations:

1. Anchor Bolt Connections

While any size bolt could theoretically be designed for the Structure to Caisson connection, the loads usually dictate that larger bolts be used. Since A615-GR75 14J and 18J bolts are specifically mentioned in ASCE 48 for anchor bolts, they are often used for this caisson connection. These bolts can be milled down and fully threaded to make the connection and still give leveling capabilities used in normal concrete foundations.

Anchor bolt circles can be positioned inside or outside the caisson wall based on the project's specifications, with neither option being inherently superior.

2. Foundation Sizing

The diameter and embedment depth of the foundation depend on soil conditions and the foundation reaction loads provided. Maintaining a relatively similar size between the caisson and the structure's bottom is advisable, the goal being to keep the anchor bolt circle close to both the Structure wall and the caisson wall for a more efficient flange plate design.

3. Driving Ears

Robust driving ears are crucial components of the caisson, mounted on top of the flange plate used for the structure connection.

Welds and construction must withstand the forces generated by the vibratory hammer during installation. (A simple fillet weld is typically not enough to withstand these forces.) A minimum wall thickness of 3/8 in. is recommended. Once the caisson is put in place, the ears are either cut off or knocked off and touch-up galvanizing is used over the exposed bare metal created by the removal of the ears.

Socket Caissons

While vibratory caissons are the most common choice, socket caissons are another alternative. A socket caisson can be vibrated into place like the vibratory caisson, or placed into a drilled hole. If the caisson is vibrated into place for installation, it will need several feet at the top for the foundation to be excavated, as the structure actually sits inside the socket caisson on a “floor” once the caisson is in place. Sometimes bolts are added to the sides of the caisson to act as plumbing agents to help plumb the structure. Once the area is plumb, the area between the structure and the caisson, usually between 3 and 9 inches, is filled with grout or concrete, which adheres to both the structure and the caisson. The biggest benefit of a socket caisson is that it eliminates the need for a flange plate connection between the caisson and the structure, which can include additional costs based on the thickness and width of the flange plate.

Considerations for Socket Caissons

Similar to the vibratory caisson, a foundation engineer will need to size the foundation diameter and embedment depth according to the soils at the job site and foundation reaction loads. The depth that the structure is socketed into the concrete allows the transfer of the loads from the structure into the caisson and then into the ground. With this type of caisson, the vibratory ears have to be placed on the caisson's walls since the top has to remain open for the structure to enter it.

Caissons offer a versatile and effective foundation solution for structures located in areas with soft soil conditions or where vibration is a concern. Their rapid installation time and cost-effectiveness make them particularly appealing for projects with tight schedules and budgets. If you are considering caissons for your next construction endeavor, consult with a qualified engineer to determine if this alternative foundation method aligns with your project requirements.

Click HERE to consult with one of our qualified engineers today.