Welding is not merely a trade; it's an art form, a science, and a crucial aspect of countless industries worldwide. It’s an exciting career that requires precision and detail and offers many opportunities. Let’s celebrate National Welding Month and dive deeper into this rewarding career.

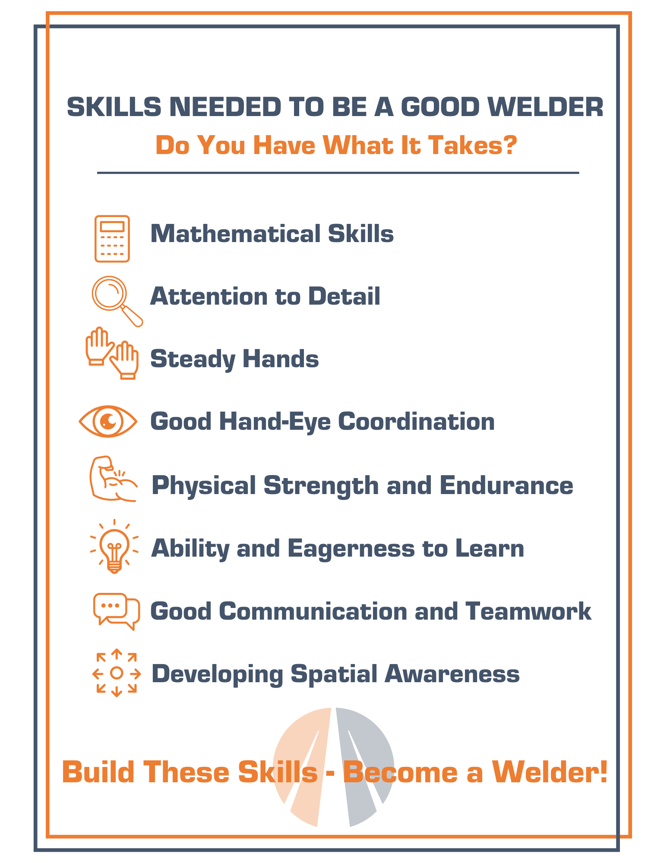

Who Should Be a Welder?

Acquiring essential welding skills is crucial for a prosperous career in the field. Whether these abilities come naturally or through practice, aspiring welders must dedicate themselves to refining them diligently.

Welding Processes and Cutting Methods

There are more than 40 different processes of welding and dozens of steel-cutting processes, so figuring out which one sounds most interesting to you is important. Below we’ve listed 4 of the most common welding methods in the steel structure industry and 1 cutting method:

MIG Welding (Metal Inert Gas)

The term MIG welding is generally used to describe a gathering of most wire welding processes. Inside this group, you will find that one of the main processes associated with production is GMAW (Gas Metal Arc Welding). There are 4 transfer modes of GMAW, with the most common one being GMAW-spray. GMAW-spray is currently one of the most used forms on the market, as well as one of the hottest and best penetrating forms of welding. Your street clothes don’t last long due to the heat and UV rays associated with this mode. For production, the GMAW process is a good choice because it is cost-efficient and speedy. However, due to requiring a decent size setup to run this method, as well as shielding gas, positions and weather could limit where and how this method is used. For example, being outside, 200 feet up in the air on a crane with strong winds wouldn’t work well for GMAW welding.

TIG Welding (Tungsten Inert Gas)

Tig Welding is mainly associated with thinner and special metals like aluminum and stainless steel. It offers lower heat input and is easier to control the puddle. This method uses a shielding gas, a tungsten torch, and typically a filler rod. Because of the torch and rod, this method generally requires both hands to perform and requires more precision from the welder. TIG welding is slightly more expensive and can be one of the slower methods because it requires great hand and eye coordination. (Which by the way would be a great PLUS on any welder’s application.

Stick Welding (SMAW)

This method is considered “old school,” since this is pretty much where it all began. It requires no shielding gas and can be used in a variety of different circumstances. The rods that are used are abundant and somewhat inexpensive compared to the filler metal costs of other processes. This method probably isn’t the most efficient in production due to the amount of time it takes to stop and change rods, and since the rods must be stored in ovens at a certain temperature. Another challenge is making sure you have the right rod for the right job (there are many different rods and diameters to choose from.) However, this is an excellent repair procedure because usually repairs are small and there is no limit, so you can weld outside, high in the air, underwater and so on. It is also one of the most common welding processes, however, it can be more difficult to master than the Mig process for some.

Flux Core Welding (FCAW)

This method is similar to the MIG processes because it also uses wire filler metals, and it is one of the more common methods behind GMAW. Flux core arc welding is a self-shielded process that creates a slag on top of the welds which must be removed in between passes and layers. One of the main differences is the inside of the wire: the filler metal wire has chemical components manufactured into it for strength purposes and compatibility with different steels. For FCAW, the flux, which protects the welded metal from the atmosphere, is located on the inside of this wire. (Hence the name flux core.) The flux cored wire comes in many different chemical makeups and therefore can be used in production to meet special needs, like different materials. This method doesn’t quite have the range of heat that GMAW-spray has, but it is still beneficial in special cases. While this method is considered fast, it is not as penetrating as GMAW-spray.

Oxy Fuel Cutting (OFC)

This is not necessarily a welding method, but it is a process that is closely associated with welding and is quite often an extremely beneficial job skill for fabricators in the steel fabrication industry. This is a process commonly used to cut steel. It’s usually accomplished with two gases; one source of ignition gas (commonly acetylene) and one source of pressure gas used as an oxidizer to quickly intensify the heat and blow the molten steel away (oxygen). It’s fairly simple to use, however, safety is a big concern when using this cutting method. It can be dangerous in the sense that there are generally a lot of hot particles being blown away and it requires work areas to be clean and free of any flammable materials. Another concern to be aware of is that all bottles of cutting gas are pressurized and must be protected. If the top of a bottle were to get damaged or knocked off somehow, it would be equivalent to a missile going off!

Steps to Become a Welder

There are many ways for those interested in a career in welding to start taking steps for success. For high school students, there are elective classes, dual enrollment classes, career days, job shadowing, and other school-provided opportunities. Some technical schools will also provide workshops during the summer for students to take part in, so reaching out to your local trade schools is a great first step. There is also an abundance of videos on the internet teaching different techniques, definitions, and other related information.

The AWS is also a great resource for all things welding. They offer information for students, safety and quality standards, career paths, certifications, and other educational resources. There are local AWS chapters across the country that are made up of professionals and those passionate about the field who can answer questions and lead you in the right direction.

Start Your Career Today

By mastering the necessary skills, exploring different welding techniques, and following a structured pathway, aspiring welders can start a rewarding career. At DIS-TRAN Steel, we remain committed to excellence and delivering unparalleled quality in every project we undertake. Our welders are not just fabricating steel; they're creating the foundation for transmission lines and substations that send power to the entire country.