When you think of a galvanizing kettle, you might only think it’s a bunch of hot melted silver stuff. But in fact, there are several different types of zinc used for hot-dip galvanizing, as well as other materials that make this protective coating.

Here are 5 types of zinc for continuous hot-dip galvanizing:

- London Metal Exchange (LME) Grade

- Special High Grade

- High Grade

- Intermediate Grade

- Prime Western Grade

Terminology of the 5 different grades

LME is a grade of zinc containing a minimum of 99.995% zinc

SHG is a high purity grade of zinc containing a minimum of 99.990% zinc

HG is a grade of zinc containing a minimum of 99.95% zinc

IG is a grade of zinc containing a minimum of 99.5% zinc

PWG is a grade of zinc containing 0.5 to 1.4% lead, and a minimum of 98.5% zinc

Galvanizers were mainly using PWG up until the 90s when the industry started to gravitate towards high grade or special high grade due to more talk and discoveries about lead. Today, galvanizers try to limit the amount of lead that is used in the process, but the percentage is tilted and doesn’t necessarily mean that all galvanizers practice this.

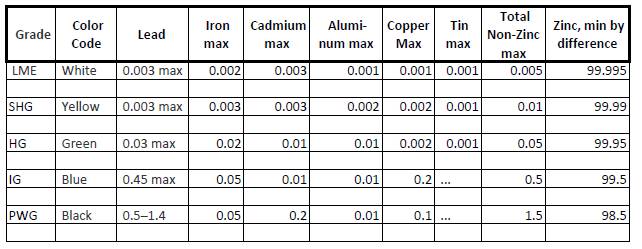

The chart below shows the composition breakdown of each grade of zinc.

There are distinctive looks and markings on the finished galvanized product depending on the grade used. For example, PWG lends itself to a more spangled look, whereas SHG has a more continuous bright coating.

No matter which type of zinc is used, all galvanized steel will start dulling after about six to eight months. While zinc certainly has a “say so” in the look of the galvanized product, the chemistry of the steel is the most important determining factor.

Service life of galvanized steel?

There are two factors that influence the service life for hot-dip galvanizing:

- Amount of millage

- Geographical location