Appearance can determine a lot just to the naked eye. Without knowing any specifics, when we look at something we instantly decide if we like it or not, just by its’ appearance. And over the years, we’ve all either heard or actually experienced that the saying “you can’t judge a book by its’ cover” tends to be true more times than so.

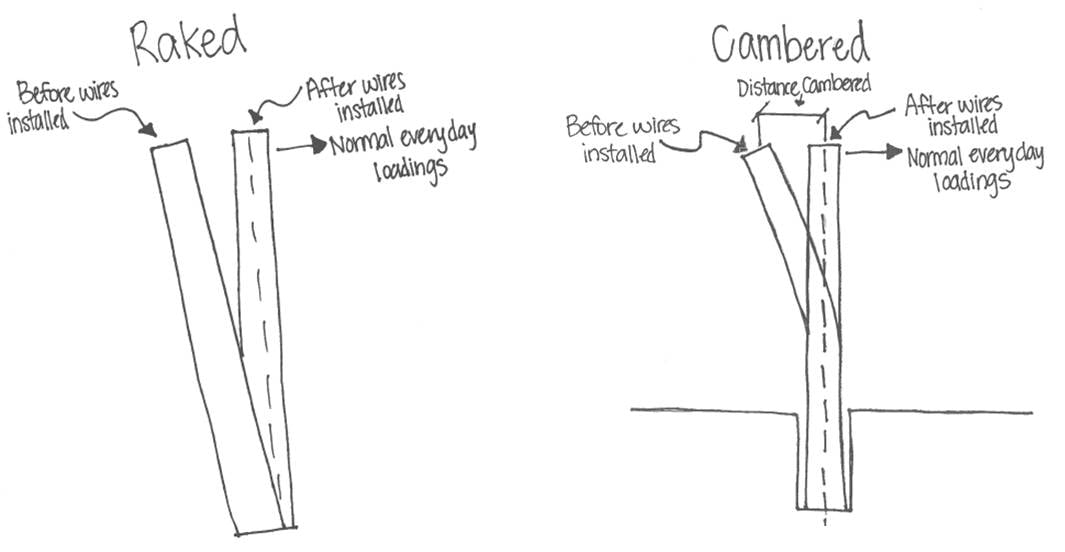

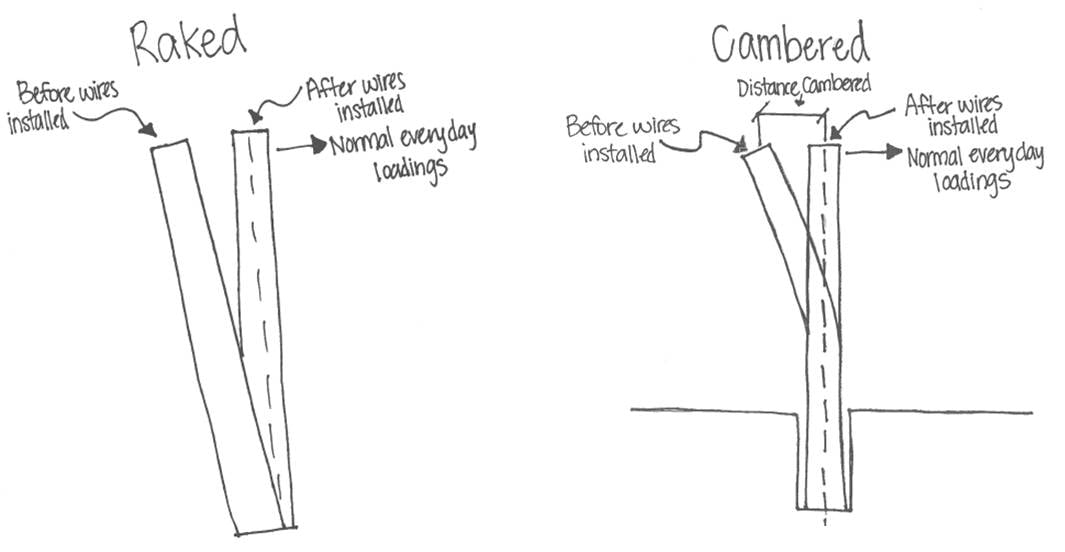

The desired appearance of installed structures can determine things like structure diameter, taper and deflection restrictions. Line angles and unbalanced phase arrangements can create loading situations that will cause a structure to deflect noticeably under normal everyday loadings. There are several methods that are used to lessen these effects, but two specific methods for counteracting monopole structure deflections due to line tensions are raking and cambering.

Both methods are used to accomplish the same goal of making the steel transmission pole appear plumb, meaning straight, under normal everyday loadings. Steel pole structures can be quite flexible. Depending on the loadings, configurations, etc. a steel pole can have a significant amount of deflection, yet be structurally adequate.

In lieu of increasing the size and/or stiffness of deflection controlled poles to decrease the amount of deflection, they can be raked or cambered. This helps avoid concern from the general public who could misinterpret noticeable deflection to appear like the pole is about to fall over. So, what is the difference in raking or cambering a steel transmission pole?

Raking- the deflection at the top of the structure is determined, and the pole is tilted a corresponding amount so that the top of the structure is at a specified position in relation to the structure at ground line. (ASCE 48-11)

Cambering- cambering the structure during fabrication to offset the anticipated deflection under load so that it will appear straight and plumb after installation. (ASCE 48-11)

Raking is when the contractor “tilts” the pole in the opposite direction of the expected deflection before the overhead lines are installed. This can be achieved by adjusting the leveling nuts below the baseplate on the anchor bolts. The amount of rake is typically based on the expected deflection under the normal everyday loading. Also, the amount a pole is raked is typically limited to lower values. For example, if a pole is deflecting less than the allowable deflection under the normal everyday loading, then the remaining deflection is taken out by raking the pole. After a pole is raked and all lines are installed, the structure will then deflect back towards the upright position appearing plumb.

Cambering is when the base plate is horizontal but the actual steel pole is curved, kind of resembling a banana. To achieve this method, selective applications such as heating and cooling cycles are used to apply curvature along the length of the pole, which is a specified amount based on the expected deflection under the normal everyday loadings. The contractor then installs the pole so that the pole curves away from the expected deflection. Once the pole is erected and all overhead lines are installed, the pole will deflect back towards the upright position appearing plumb.

Specifications sometime require a pole to be raked if the deflection is less than 1 percent of the normal everyday load case, and to be cambered if the deflection exceeds 1 percent.

If the pole is to be raked, then the pole is designed for all load cases ensuring the structure does not overstress, while at the same time does not deflect more than 1 percent under the normal everyday loadings.

If the pole is to be cambered, then the pole is designed for all load cases ensuring the structure does not overstress while at the same time not limiting the deflection.

3 things associated with curving a pole to keep in mind are:

1. Possible additional costs

2. Maintaining the needed curvature during the galvanizing process

3. Limitations of this method on thicker/larger shafts or shafts with a lot of attachments and thru-vangs.

However, in using this method for deflection controlled monopole structures, there could be overall cost savings by allowing more deflection resulting in smaller/ lighter poles.

In a previous blog we talk about when to use concrete pier foundations over direct embedded foundations, so just to point out an advantage that concrete foundation has over an embedded pole is that the pole can be easily raked with the anchor bolt leveling nuts. Depending on site conditions and equipment in the field, there can be challenges to maintaining the needed rake as backfill is added around the embedded pole. When raking, the differential of the nuts are not much compared to the entire structure, therefore making it easier for the fabricator and providing more control in the field for the contractors. When a pole is cambered, it can be at times like mixing art and science together.